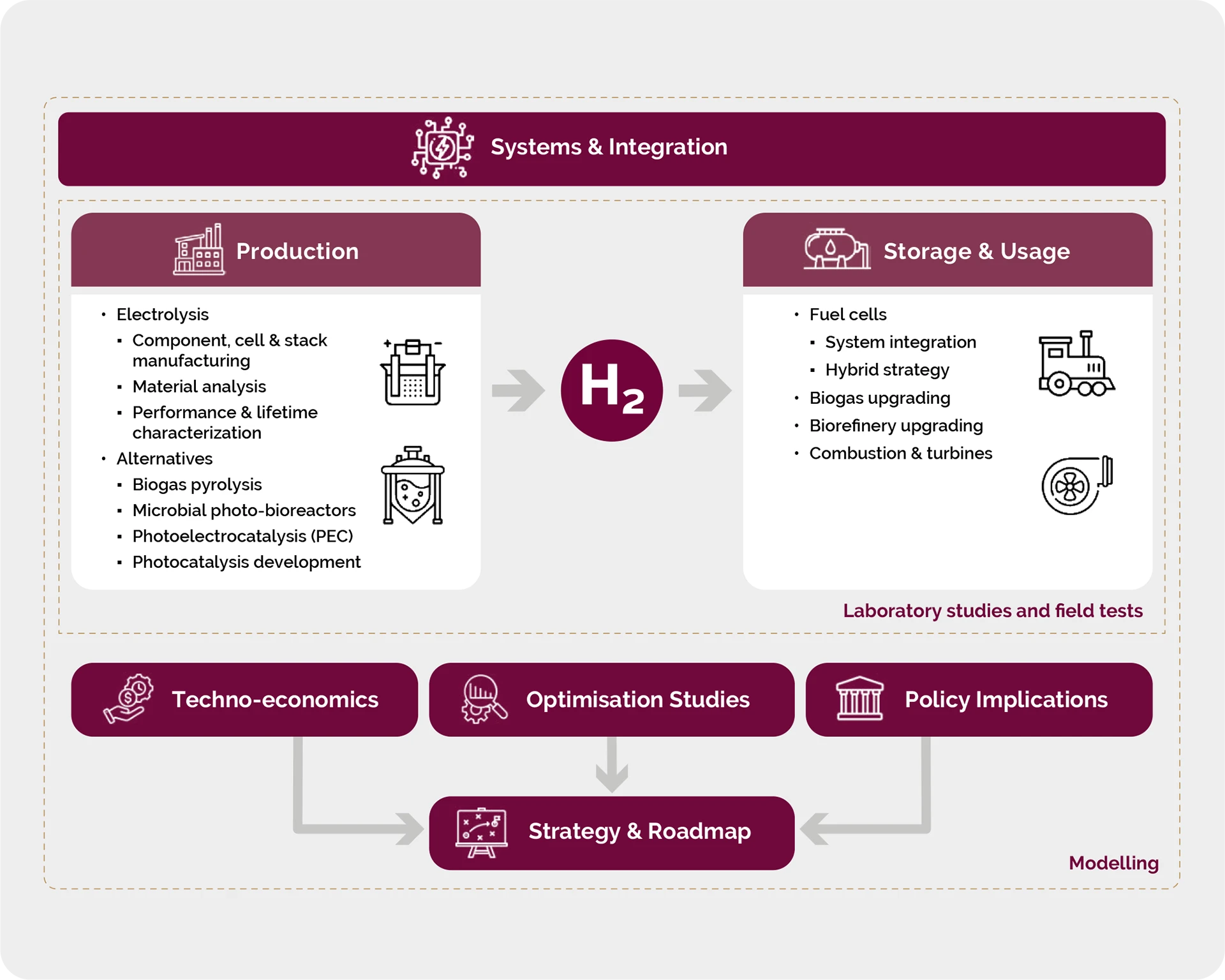

The Hydrogen Generation and Energy Network (H2GEN) at Stellenbosch University presents a platform for extending South Africa's reach in the global hydrogen economy. By leveraging the country's abundant renewable energy resources in alignment with the national green hydrogen roadmap, H2GEN addresses critical knowledge gaps in hydrogen engineering through research across various engineering disciplines.

Why Hydrogen?

Green hydrogen presents a strategic solution for South Africa's renewable energy transition. Produced through electrolysis powered by renewable energy or alternative routes, hydrogen enables long-duration energy storage and transport, addressing the temporal and spatial mismatch between renewable energy generation and demand. This positions hydrogen as a critical enabler for decarbonizing hard-to-abate sectors while maximizing the value of South Africa's exceptional renewable resources.

Our Vision

To position Stellenbosch University as the premier partner for international research projects and leader in clean hydrogen systems engineering in South Africa.

Our Mission

To establish a state-of-the-art, multi-disciplinary hydrogen laboratory that drives innovation, fosters collaboration, and develops highly skilled professionals in the green hydrogen sector.

I. Production

Research on hydrogen production includes electrolysis with a special focus on material development to reduce the use of precious metals and alternative manufacturing methods. On the other hand, alternative production methods such as biogas pyrolysis, microbial photobioreactors, and photoelectrocatalysis are investigated.

Electrolyser Technology Programme:

Anion Exchange Membrane Electrolysis

A less cost-intensive alternative to PEM is anion exchange membrane (AEM) electrolysis, which is an emerging water-splitting technology that combines the advantages of both alkaline and PEM systems.

Electrolyser Technology Programme:

Additive Manufacturing of Cell Components

Current methods for manufacturing porous transport layers (PTLs) offer limited manufacturing control over structural morphology and are inefficient in their material use.

Electrolyser Technology Programme:

Catalyst Development

The anode and cathode electrocatalysts are crucial components of the membrane electrode assembly (MEA) of the PEMWE, as they promote the half-reactions, namely oxygen and hydrogen evolution reaction (OER and HER).

Electrolyser Technology Programme:

Electrochemical Water Electrolysis

Electrochemical water splitting has long been considered an effective energy conversion technology for converting intermittent renewable electricity into hydrogen fuel.

Alternative Production Methods:

Microbial Photobioreactors

Microbial photobioreactors are specialized systems designed to harness the metabolic capabilities of microorganisms, such as algae and bacteria, under controlled light conditions.

Alternative Production Methods:

Biogas Pyrolysis

Hydrogen has emerged as a promising clean energy source, with applications in various hard-to-abate sectors such as transport, shipping, cement, and steel.

Alternative Production Methods:

Photocatalysis Development

The research is focused on developing photocatalytic hydrogen-producing pathways as an alternative to standard electrolysis, both from water and hydrogen carriers such as alcohols.

Alternative Production Methods:

Photoelectrochemical Water Electrolysis

Photoelectrochemical (PEC) water-splitting technologies promise to improve on traditional PV-powered electrolysis methods in terms of sustainability, efficiency, and cost.

II. Storage & Usage

Hydrogen is used in various application technologies such as fuel cells and combustion engines, either in its pure form or as a subsequent fluid such as ammonia, the production of which in biogas plants is also investigated. Storage research currently focuses on metal hydride materials but may be extended to, for example, pressurized tanks in the future.

Biogas Upgrading

This programme aims to investigate the integration of clean hydrogen in biogas upgrading processes, focusing on biomethanation, CO₂ hydrogenation, and methane cracking.

Combustion of Hydrogen–Hydrocarbon fuel mixtures

The continued global use of gas turbines in the production of electricity and power is due to the high power-to-weight ratio, operational flexibility, and reliability of these machines.

Development of a scale-model hydrogen-propelled train

The global transition towards sustainable transportation has increasingly highlighted hydrogen fuel cells as a promising zero-emission alternative for powering various modes of transport, including rail systems.

Hydrogen Integration in Biorefineries

A biorefinery is a concept derived from conventional refineries that process various types of biomasses and the biogenic CO₂ derived from them, using thermal, chemical, biological, physical, or combined conversion methods to produce chemicals, biomaterials, advanced biofuels, and innovative food ingredients.

III. Systems & Integration

It is crucial to investigate not only the production and usage of hydrogen but also its integration into the energy system. Thus, techno-economic and optimization studies, including policy implications, are conducted to develop a strategy and roadmap for optimal implementation in the overall energy system.

Power-to-X Systems Integration

South Africa’s energy system is constrained by aging coal infrastructure, rising fossil fuel import dependence, grid capacity limitations, and increasing pressure from international trade partners adopting carbon pricing mechanisms.