Hydrogen Integration in Biorefineries

Background

A biorefinery is a concept derived from conventional refineries that process various types of biomasses and the biogenic CO₂ derived from them, using thermal, chemical, biological, physical, or combined conversion methods to produce chemicals, biomaterials, advanced biofuels, and innovative food ingredients. Some biorefinery processes for biomass or biogenic CO₂ use hydrogen as a raw material to produce chemicals (e.g. 1,2-propanediol, methanol, sorbitol, methyl tetrahydrofuran, tetrahydrofuran, gamma-valerolactone, 2-methylfuran, cyclohexane, and cyclohexanone), bioplastics (polylactic acid, polyethylene), and sustainable aviation fuels. In addition to providing access to various kinds of biomass materials (molasses, lignocelluloses), sugar mills provide an ideal opportunity for utilization of biogenic CO₂, including fairly pure CO₂ from bioethanol distilleries and less-pure CO₂ from biomass-fired cogeneration systems. When combined with green hydrogen, biogenic CO₂ offers a pathway to decarbonize the chemical and fuel sectors while supporting global energy needs.

Although the aforementioned processing options will benefit financially from the use of low-cost, fossil-based (grey) hydrogen, the replacement

of grey hydrogen with green hydrogen to enhance environmental sustainability remains crucial. Sugarcane biorefineries using green hydrogen, typically integrated with sugar mills and associated facilities that produce biogenic CO₂, have shown environmental advantages but often suffer from poorer economic performance due to the increased cost of production. Green hydrogen is typically obtained by either importing or self-producing renewable electricity for electrolysis in these biorefineries; some process residues are also suitable for anaerobic digestion or gasification, followed by reforming and purification of bioderived green hydrogen. Finding markets willing to pay a premium for improved decarbonization potentials of hydrogen-derived products is critical to commercial feasibility of these biorefineries.

Current Activities

First research activity

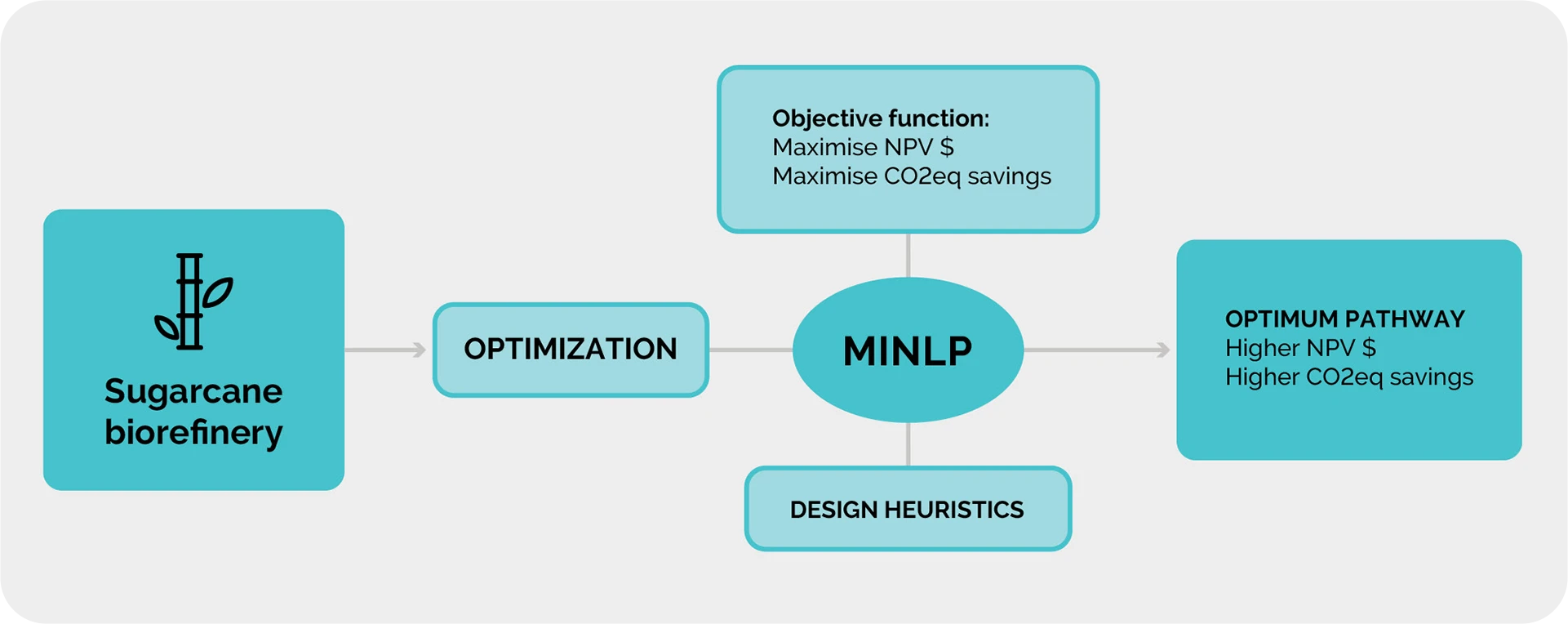

Given these challenges, the first (current) research project focuses on optimizing sugarcane biorefinery processes that use biomass materials in combination with green hydrogen and exhibit a trade-off between economic and environmental performance. Mixed-integer nonlinear programming (MINLP) will be used as the optimization strategy to determine an optimal pathway that provides a balance between its economic and environmental performance. This will be carried out by first defining the multi-objective functions, for which the economic objective function may involve maximizing both the net present value (NPV) and the equivalent greenhouse gas emissions savings (measured in CO₂ equivalents) for the environmental objective function. The multi-objective model will be formulated to capture the interactions between these two objectives by incorporating decision variables and constraints that influence both economic and environmental performance. Solutions of a particular process will be determined for a defined number of design scenarios, distinguished by certain processing aspects such as pretreatment and bioconversion methods used, and separation technologies employed. The optimum pathway will reveal a higher NPV for the same or higher equivalent CO₂ emission savings, or alternatively, higher equivalent CO₂ emission savings for the same or higher NPV.

Summarized methodology for optimizing sugarcane biorefinery processes using MINLP

Second research activity

The second project entails conducting comparative techno-economic and environmental performance evaluations of a sugarcane biorefinery integrated with biogenic CO₂ conversion with green hydrogen. Using an Aspen Plus® process simulator, several biorefinery processes to produce methanol, sustainable aviation fuel, formic acid, and dimethyl ether are rigorously simulated. Both direct CO₂ hydrogenation and indirect routes via methanol and syngas-mediated steps are explored. The study also compares hydrogen supply options, assessing the use of imported green hydrogen versus on-site production via plant-derived or externally sourced renewable electricity. Capital cost, operating cost, and profitability of scenarios such as minimum selling price will be used to ascertain the differences in the economic performances of various technical variations and configurations. Life-cycle assessment will be used to determine the environmental robustness of the biorefinery scenarios. The quantities and likely market prices for carbon credits (green premiums) will link the environmental and financial aspects of these scenarios. The results would provide valuable insight into the preferred biorefinery configuration, considering process selection that is both financially viable and environmentally beneficial.

Third research activity

A third research activity considers the stepwise, incremental replacement of coal in South African synthetic fuel manufacturing facilities with a range of alternative carbon sources to produce hydrogen-rich syngas. The goal is to propose the most financially and environmentally viable transition from the current use of coal as only gasification feedstock to alternative sustainable carbon-sources and green hydrogen. Aspen Plus® simulation models of a wide range of co-gasification process scenarios are explored for technical, economic, and environmental synergistic benefits. This methodology will account for expected future decreases in green hydrogen costs and expected increases in carbon taxes driven by environmental policies. Subsequently, promising process configurations will be identified for medium- to long-term renewable energy transition.

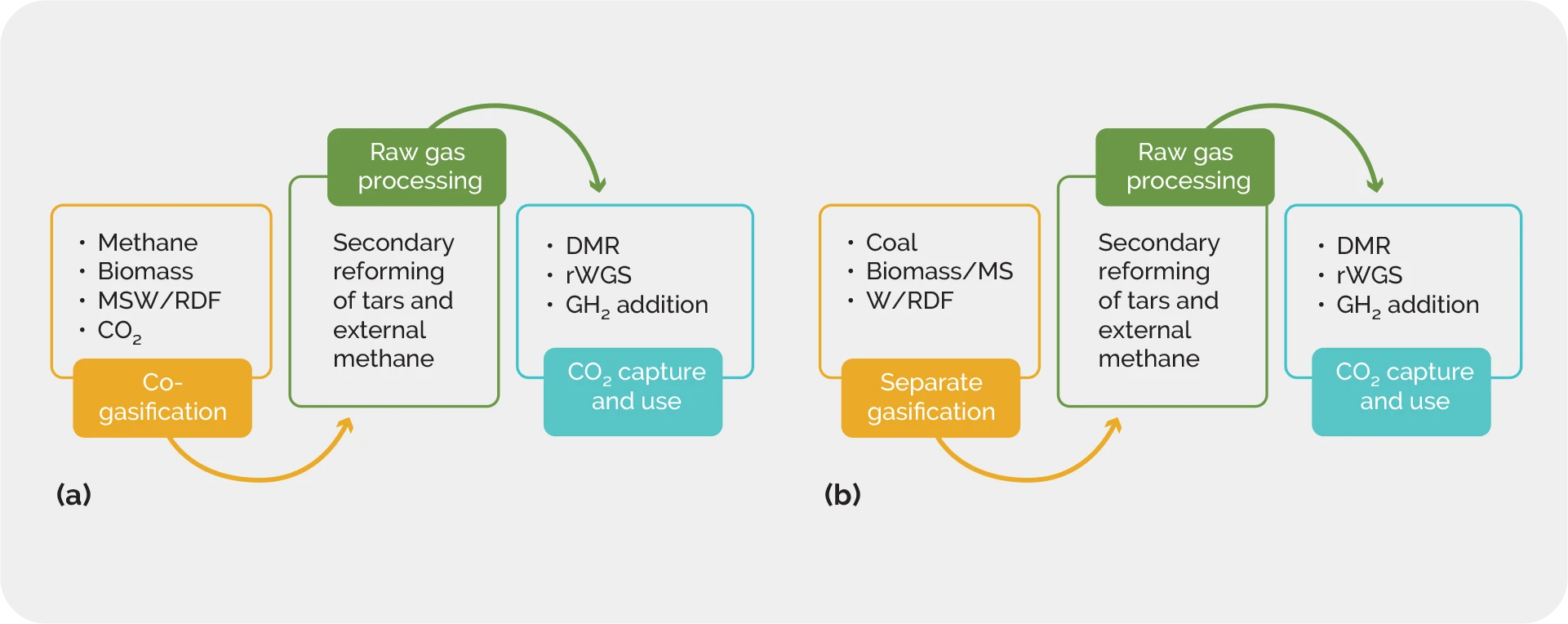

The gasification scenarios combine the co-gasification of coal with sustainable carbon, steam methane reforming (SMR), dry methane reforming (DMR), and green hydrogen from water electrolysis. Biomass, municipal solid waste and refuse-derived fuel (MSW/RDF), biogas, natural gas, and captured CO₂ are considered for either co-gasification with coal, or separate/dedicated gasification, in a pressurised, fixed-bed updraft, bottom-ash gasifier, as indicated below. The resulting raw gases are combined and undergo a similar co-reforming process in both approaches. A combined steam and dry methane reforming system is proposed, where SMR and DMR are arranged in a series–parallel configuration. The raw gas from the gasifier is co-reformed with methane from natural gas or biogas in SMR unit, producing raw gas that is subsequently cleaned in acid gas removal (AGR) unit. The captured CO₂ is then processed with either methane in DMR or green hydrogen in reverse water gas shift (rWGS) to produce additional syngas that is combined with clean syngas from SMR unit. In the case of green hydrogen addition, hydrogen is mixed with clean syngas from DMR to optimize the H₂/CO ratio, with the green hydrogen produced through water electrolysis powered by renewable electricity.

(a) Co-gasification and (b) separate gasification process integration approach